Illumina Fluid Cartridge Design Project

Feb 2023 - June 2023

As part of my senior capstone project at UCSD, sponsored by Illumina, I was fortunate to be part of a team of five engineering students working towards enhancing the efficiency of Illumina's genome sequencing products. Over a span of 12 weeks, we were tasked with optimizing the mixing process of reagents with different viscosities and densities. After a rigorous design process, precise manufacturing, consistent data acquisition, quantitative analysis, and persistent collaboration with industry contacts, we successfully developed an innovative mixing strategy which increased mixing efficiency by 290%.

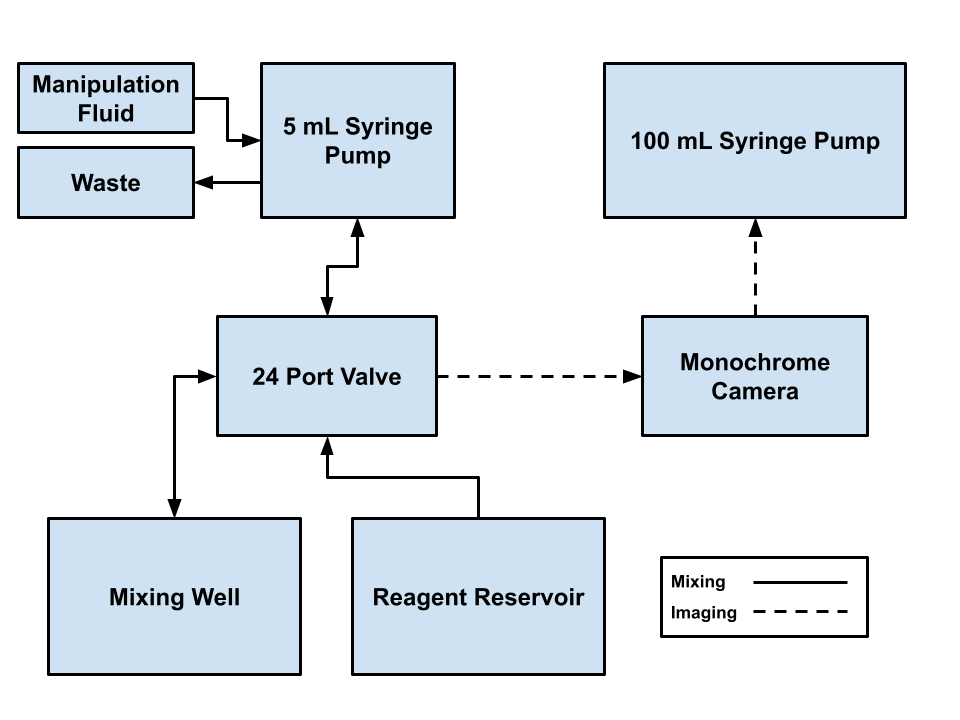

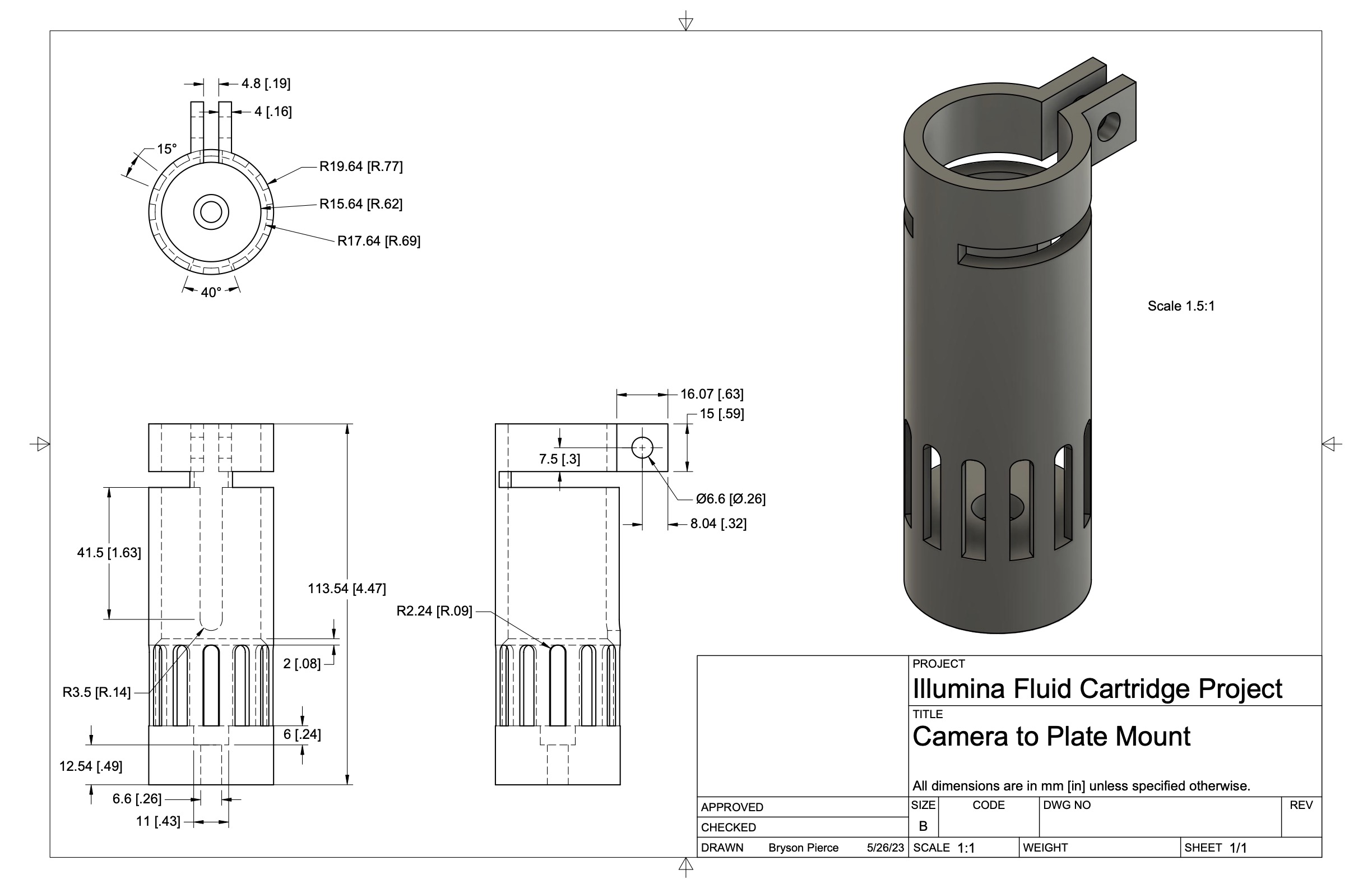

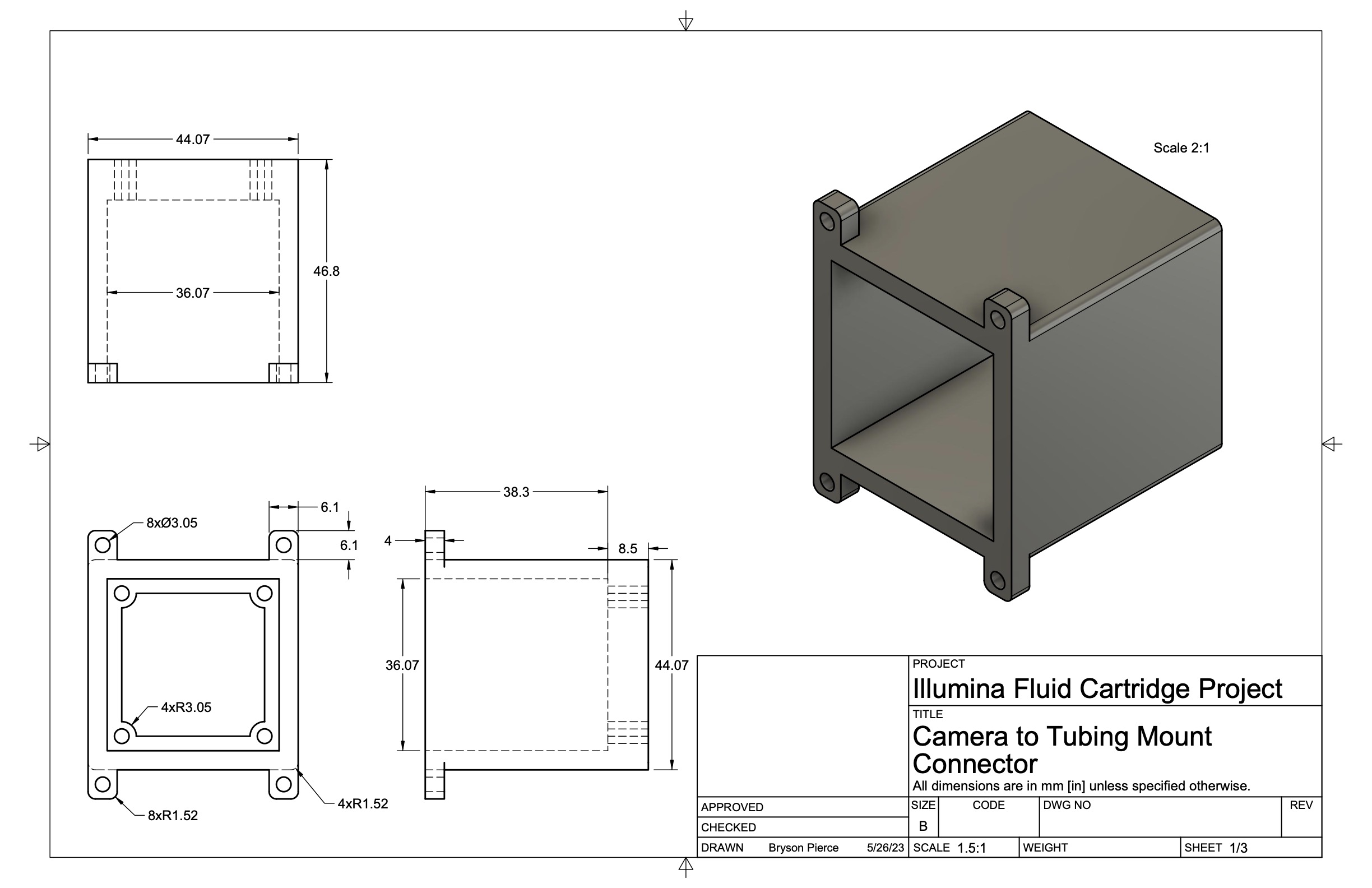

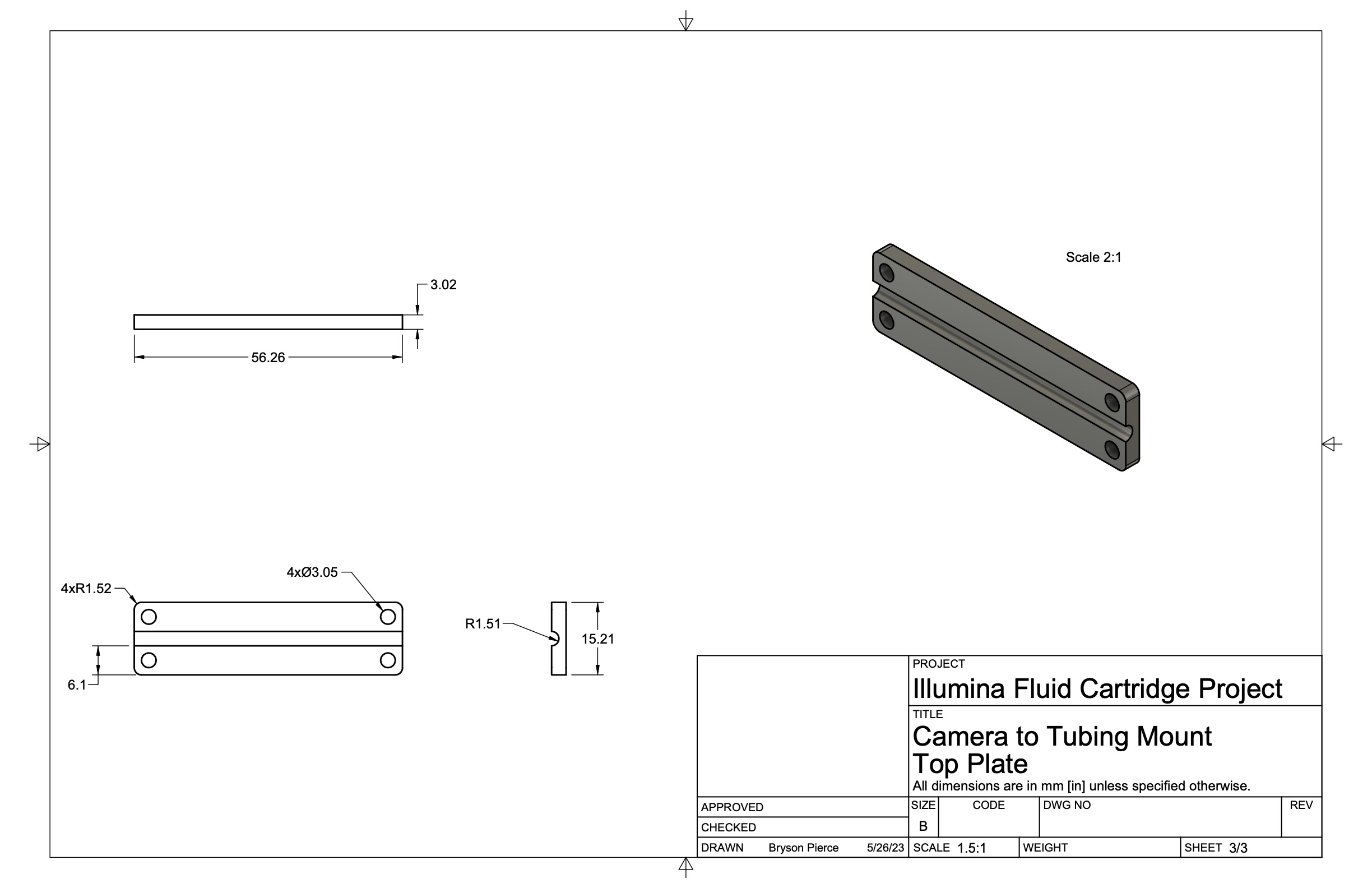

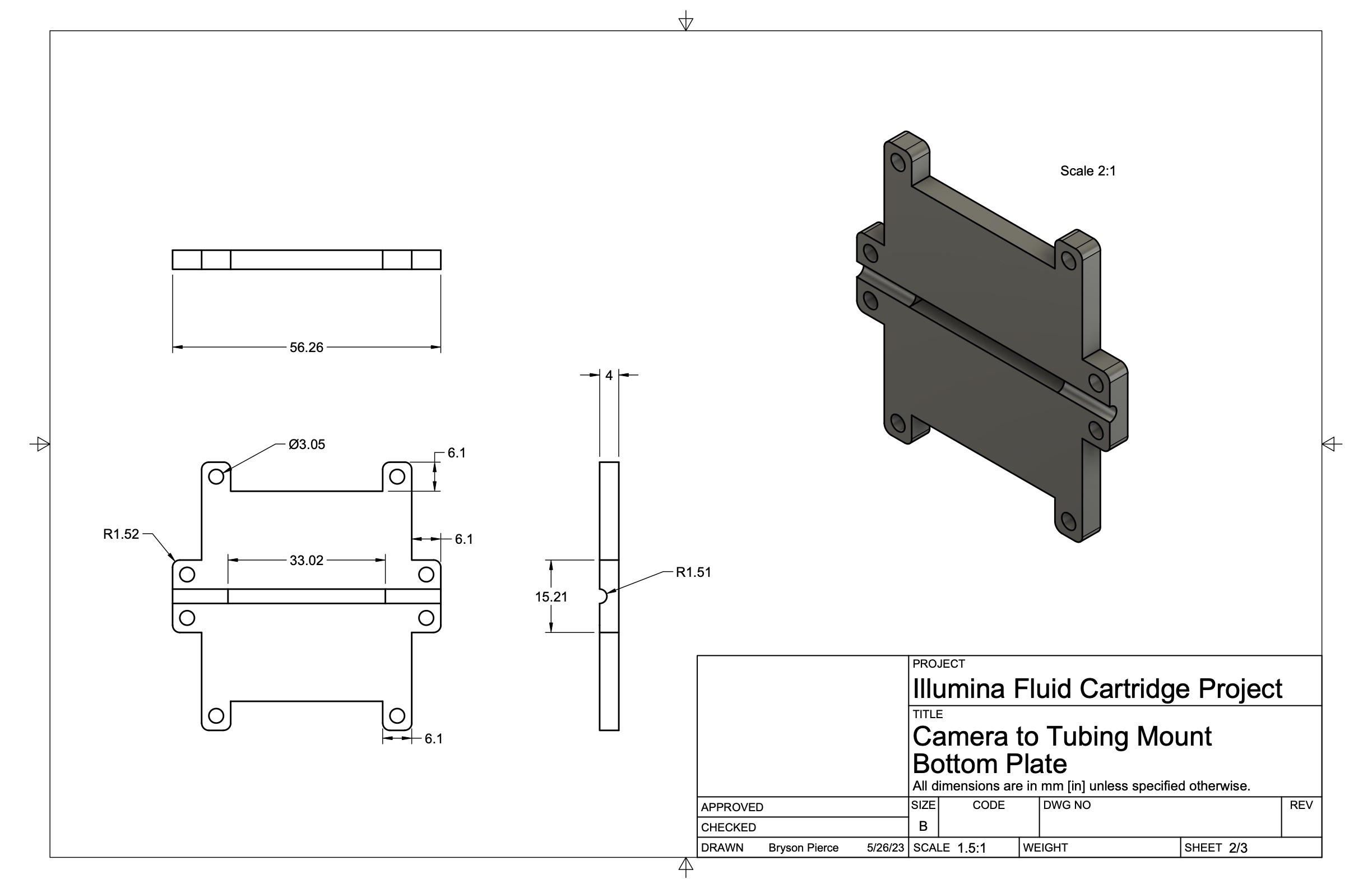

Within the team, I took on the role of leading the Data Acquisition and Analysis subteam, where I was responsible for designing the test bed, developing the testing procedures, and drawing design conclusions from subsequent analysis. To ensure accurate data collection, I created custom mounts using CAD software (SolidWorks and Fusion360) and 3D printing. These designs guaranteed a stable camera setup, consistent placement of the tubing relative to the camera, and a pitch-black environment to accommodate the highly-sensitive, 16-bit depth, fluorescent-filtered camera. Although I cannot share photos of the full test bed due to IP concerns, I’ve included the test bed diagram and my custom mount designs below:

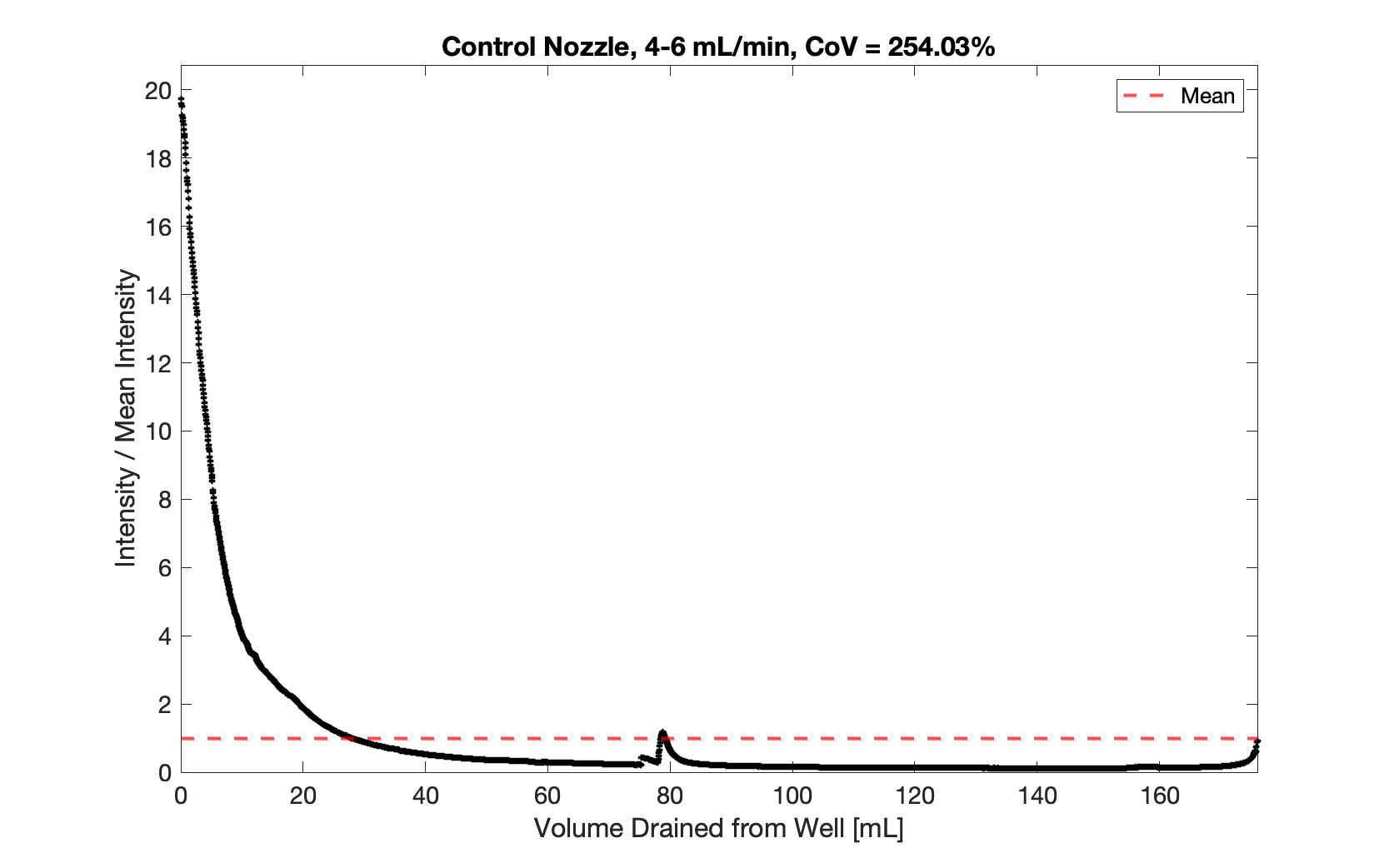

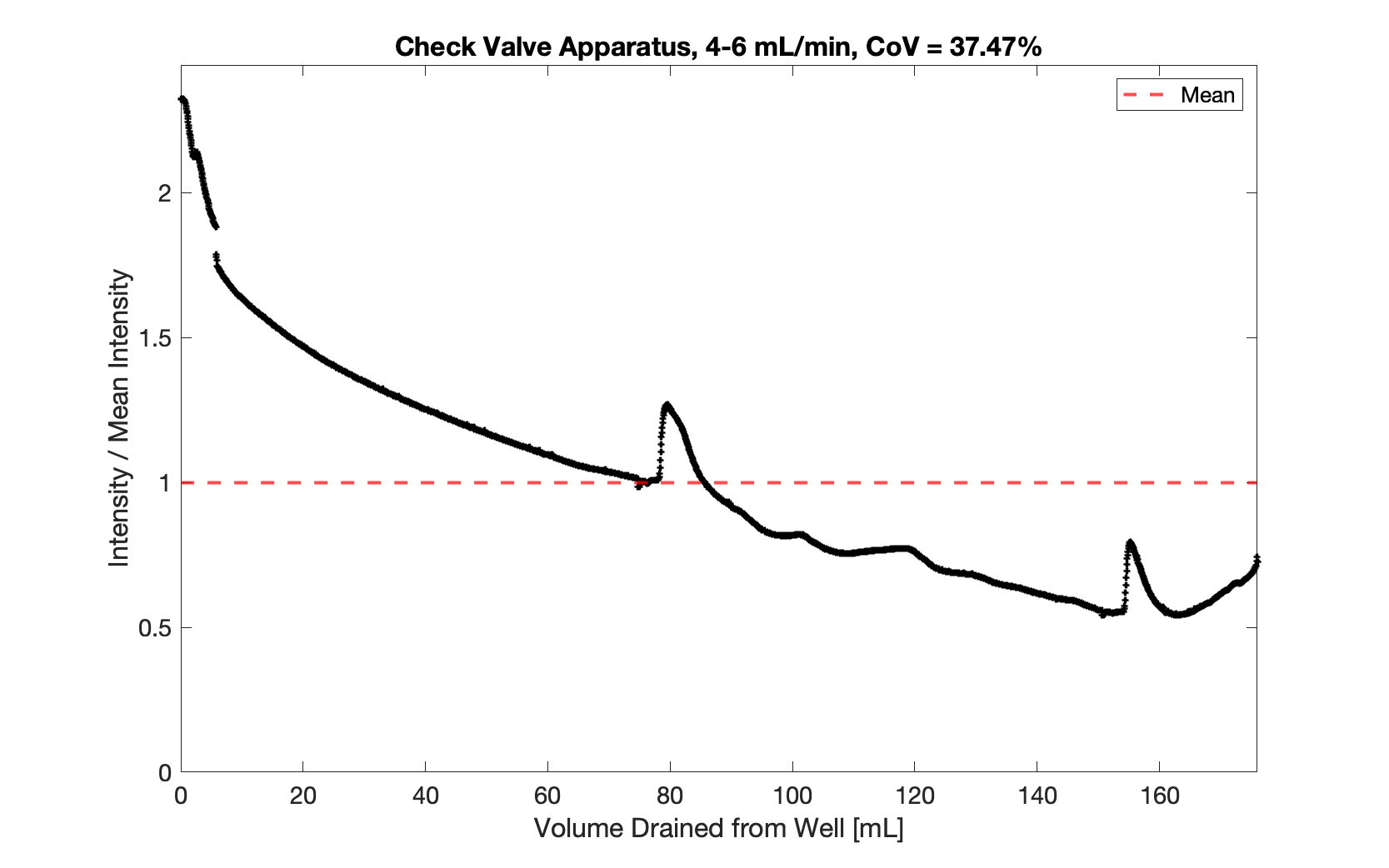

To streamline the experimentation process, I utilized custom LabView software to automate tasks such as fluid line priming, reagent introduction, mixing, and data acquisition. After data collection, I employed my custom MATLAB scripts for the processing and analysis of over 3,000 images obtained per test. By quantifying pixel intensity data and employing statistical analysis, I determined the resulting efficiency of mixing. I utilized the Coefficient of Variation (CoV) of the entire dataset as a metric to measure inhomogeneity, with lower CoV values indicating better mixing performance. Illustrated below are two of the tests conducted: one of the control strategy, and one of our final design.

Although my primary focus was leading the data acquisition and analysis efforts, I also made substantial contributions to the design team. I provided valuable feedback and insights on Design for Manufacturability (DFM) and manufacturing processes, ensuring that the designs met functional restrictions and requirements. Additionally, I conceptualized and proposed several designs, one of which was implemented as our final successful prototype—the "Check Valve Apparatus." I guided the design process by drawing a schematic, suggesting necessary parts, assembly methods, and manufacturing considerations. After the design team successfully manufactured the prototype, I conducted comprehensive tests that revealed an average 290% increase in performance compared to the control—a nearly fourfold improvement. This final prototype is pictured below:

In addition to my role in data acquisition, analysis, and design, I assumed my responsibility as fiscal manager for the project. This involved tracking the project's $5,000 budget, documenting all purchases, and handling purchase requests. This custom budget sheet is also publicly available here. I also actively communicated with industry representatives through emails and calls on a regular basis to ensure timely acquisition of components and to secure the best-suited resources for our project needs. By efficiently utilizing our budget, I successfully generated over $3,500 of surplus, resulting in significant cost savings for Illumina.

If you would like to explore the project in more detail, I invite you to read our comprehensive project report, which has been included below. The report encompasses our design process, experimental data, a detailed description of the final product, and more. Specifically, you can find my contributions in the beginning of Chapter 3 (pages 13-18), the entirety of Chapter 4 (pages 36-49), and the first section of Chapter 5 (page 50). These sections will provide further insight on what I’ve discussed thus far.

Due to confidentiality concerns, certain project specifics have been omitted both on this website and in the full report. However, if you have any questions regarding my work on this project, please feel free to contact me here. I would be happy to discuss more about my work on this project to the extent that I am allowed.